Home Page

The World’s Leader in Steering Components

Explore our areas of specialty: Engineering, Quality Assurance & Manufacturing.

Somic offers competitive salaries, comprehensive benefits, and a solid commitment to employee wellness.

Learn all about our Japanese history, our current values, and our vision for the future.

Focused On Quality.

Delivering Through Teamwork.

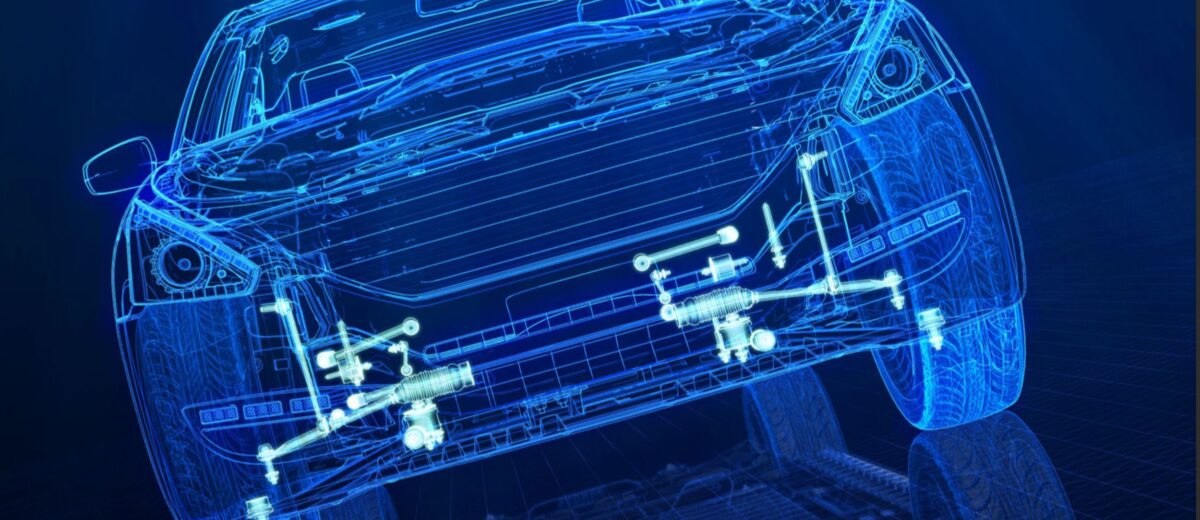

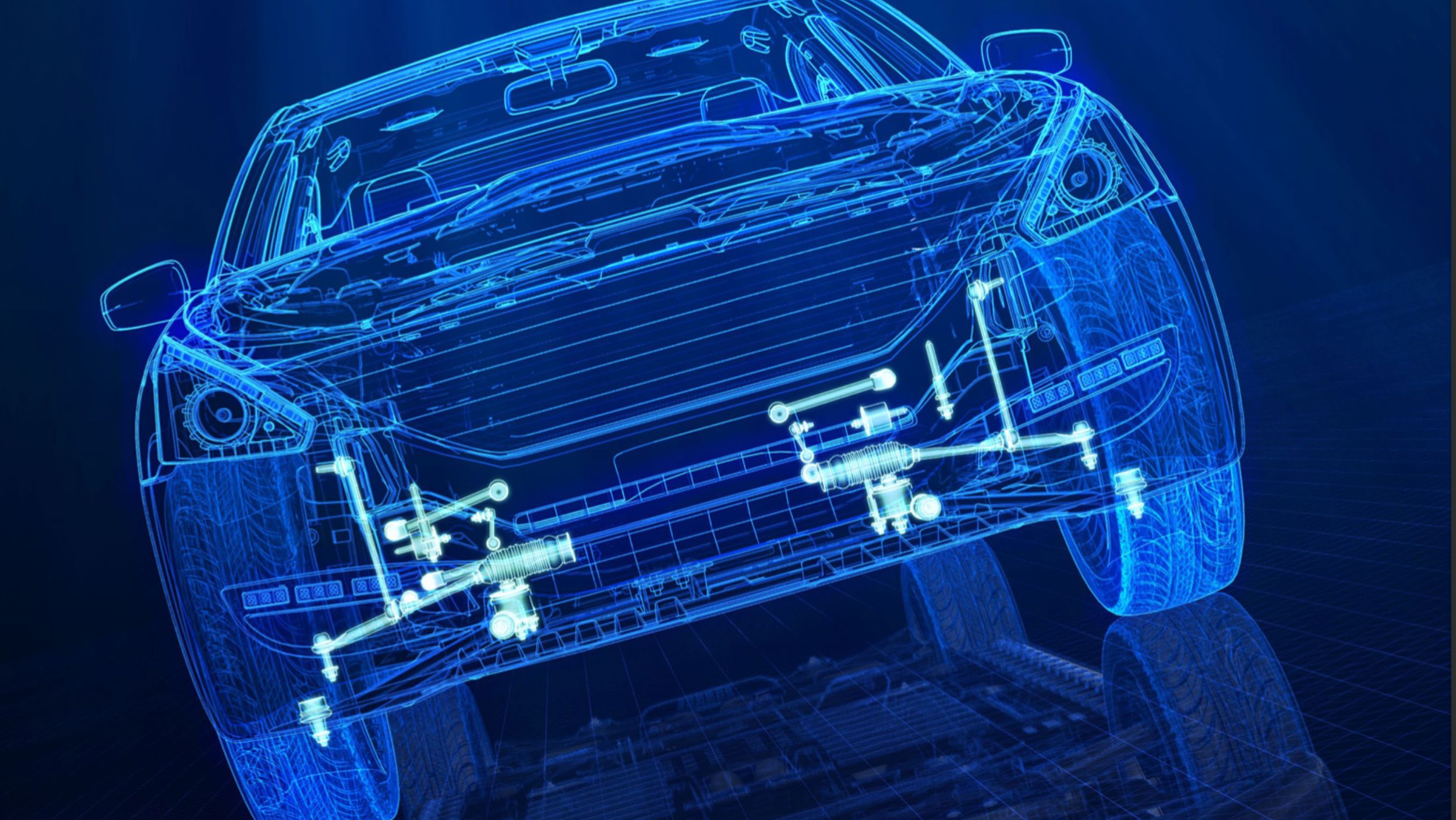

A leading supplier to the automotive manufacturing market, Somic America specializes in the engineering, design, and manufacturing of quality ball joints for suspension and steering systems, and rotary dampers for seat and tailgate applications.

Somic America focuses on creating products of exceptional quality and reliability – and supporting vehicle manufacturers in enhancing vehicle safety, reliability, and comfort.

AMERICAN PRIDE

For more than 25 years, Somic America has produced quality components for the North American and South American automotive markets, providing manufacturers with local sourcing and a connection to the exceptional capabilities and performance commitment of Somic Ishikawa.

Operating through locations in Brewer, Maine and Wytheville, Virginia, Somic America’s vertically integrated processes including manufacturing, machining, and assembly, as well as capabilities for rapid design changes.

A GLOBAL LEADER

Somic America is a subsidiary of Somic Ishikawa, a global leader in design, development and manufacture of automotive components. Established in Japan in 1916, Somic Ishikawa has continuously expanded, and now has a presence in eight countries, including Japan, China, Indonesia, India, Thailand, France and the United States. Somic Ishikawa became a Toyota partner in 1937. Today, the company continues to be respected worldwide for its strategic focus on exceptional quality and reliability. Learn more about our parent company

CAREER OPPORTUNITIES

We are a team that supports each other, collaborates on projects, celebrates success, and works hard.

We reward hard work and positivity with:

- Competitive pay

- 401K matching plan

- Paid time off up to 20 days

- 10 holidays per year

- Full insurance coverage

- Incentive bonuses.